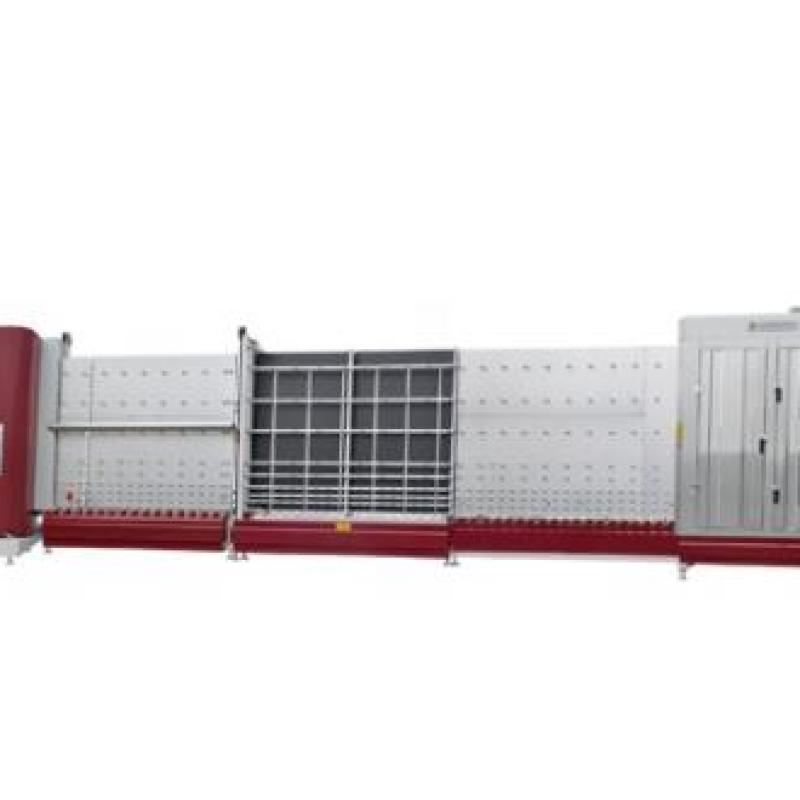

Italy Technical level of Production ,Installation and Mechanical.Japanese Panasonic transducer, Taiwan Wenview monitor, Korean Autonics sensor to keep the main electric parts running more than 50,000,000 times. All transportation running in automatic ,speed up – press glass --- two or three pieces of glass or different sizes of glass .it adjust the size of different glass by servo motor to realize high auto and more exact running.More practical and convenient design of pressing part about vacuum , pneumatic driving.

Contact Now

We adopt the most advanced technology for the butyl extruder machine;develop with utmost convenient for operation, which increases the production efficiency. Butyl is the key process in insulating glass production, only if the butyl sealing is perfect, you can get the perfect insulating glass. In order to get the proper connection between aluminum frame and glass, precise operation temperature is required.

Contact Now

Feature1. used for 45 ° glass glazing bead reducing and the attitude milling and decreasing.2. one time could slicing portions of glass glazing bead.3. with degree rulers, it could processing the glazing bead in keeping with the desired length with a purpose to ensure the precision of the processing length and remove the fan frame assembly mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

1. used for 45° glass glazing bead slicing and the angle milling and reducing.2. one time could slicing pieces of glass glazing bead.3. with measure rulers, it could processing the glazing bead in keeping with the wanted size with a view to make certain the precision of the processing size and do away with the fan body assembly blunders.4. 4 pieces noticed blade make certain unique reducing, double reducing one every give up to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead lowering and the mindset milling and decreasing.2. one time ought to slicing quantities of glass glazing bead.3. with diploma rulers, it is able to processing the glazing bead in step with the favored period a good way to make sure the precision of the processing period and eliminate the fan body meeting mistakes.4. four portions noticed blade make certain specific lowering, double decreasing one every surrender to mill the hook foot.5.

Contact Now

1. used for 45° glass glazing bead cutting and the perspective milling and lowering.2. one time ought to cutting portions of glass glazing bead.3. with degree rulers, it can processing the glazing bead consistent with the desired length as a way to ensure the precision of the processing length and cast off the fan frame meeting blunders.4. four portions observed blade ensure specific lowering, double lowering one each surrender to mill the hook foot.5.

Contact Now

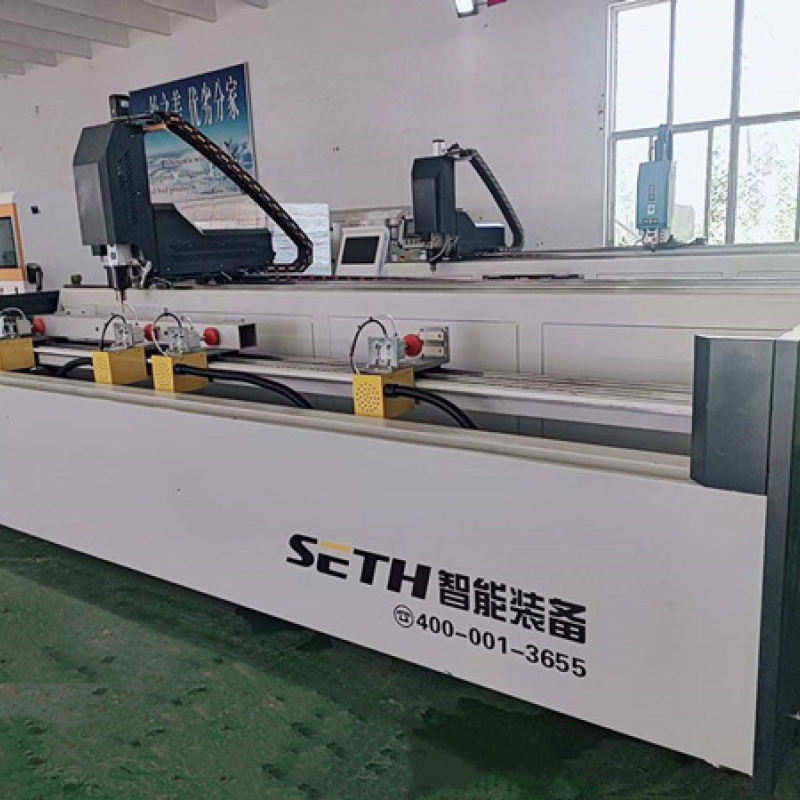

5 Axis CNC Gantry Machining CenterModel:LGS-CNC-7000Length can be customizedFeature:1、Equipment characteristics● Foolproof operation: on-line with ERP software, can realize automatic processing of scanning code.● Profile once clamping, can complete all sawing, milling end tenon, milling keyhole slot, flow tank, pressure balance hole, installation hole and other machining sequence, truly realize "one person door and window production line"● The use of moving beam moving column gantry frame structure, more stable operation, improve the machining rigidity of the machine.● The use of hig

Contact Now

1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

Feature1. used for 45 ° glass glazing bead cutting and the angle milling and cutting.2. one time could cutting two pieces of glass glazing bead.3. With measure rulers, It can processing the glazing bead according to the needed size in order to make sure the precision of the processing size and remove the fan frame assembly error.4. 4 pieces saw blade ensure precise cutting, double cutting one each end to mill the hook foot.5.

Contact Now

3 axis CNC Machining Center for Aluminum ProfileModel:DSK-CNC-3500Equipment features:● This model for the system door and window intelligent connection model, support ERP MES management software door and window software docking, to achieve the integration of production and marketing control to improve production efficiency.● Scanning sawing two-dimensional code system automatically generates round holes, slot holes, keyholes, special-shaped holes, milling, chamfering, and other processes without manual participation to reduce manual labor intensity and improve the qualified rat

Contact Now

LXDQZ-ZD-250It is suitable for forming tenons and step surfaces of various profiles, and is a special and efficient equipment for the production of doors and windows curtain walls.The machine has the advantages of fixed profiles and moving tools, andcan realize multi-quantity and multi-batch molding of long profiles.Six sets of combined cutters can be combined into any size according to users' needs, and two sets of cutters can be adjusted within 180°.The required tenon size can be milled on the profile end face by one- time cutting.

Contact Now

LJLKZ-2300It is suitable for high-efficiency drilling of hinge mounting holes, sliding support wind support holes and four-link holes of aluminum doors and windows (external windows, overhead windows, etc.).Four holes can be drilled on both sides at the same time, so the production efficiency is high, and the two heads can work independently or simultaneously.The bed of the machine tool is equipped with two heads, the left head is fixed and fixed on the bed with screws; The right head can be pulled by the handle to move on the circular guide rail and locked at the requi

Contact Now

1).this machine, it's far our common welding device, in case your profile is europe profile, it's far no problem, if your profile is america kind profile,it desires to make backup moulds consistent with the profile pattern, so if it's miles america type profile, it wishes consumer post the profile pattern to us,then we make the moulds in line with the pattern.2).in case you profile thickness(top) is better than 120mm, and also need to use this not unusual welding machine, we will make the welding head higher with a few tool,however it needs to client pay a few extra fee approximate

Contact Now

Wide Range of Use Aluminum spacer bending for insualting glass processing . Main Introduction 1. French Schneider PLC, man-machine interface, simple operation.2. French Schneider low-voltage appliances .3. Enter digital aluminum frame size.4. Aluminum strip automatic docking.5. Servo control feeding .6. Aluminum strip automatic welding function, aluminum strip welding mouth automatic avoiding7. Bend the outer is made by stainless steel guard plate.Support continuous bending of different shapes, large size

Contact Now

LJLY-CNC-350It is suitable for 90° precision cutting process of aluminum alloy glass wire pressing profile, and is suitable for mass continuous production.Bluetooth transmission is adopted, which is accurate and does not need secondary modification.Equipped with tool detection system to improve service life.Equipped with wireless hand-held transmission system, automatic material reduction function.The standard coding function is convenient for customers to use the material type without making mistakes, thus improving the utiliza

Contact Now

Power supply: 380V/50HzWorking pressure: 0.6~0.8MPaGas consumption: 8L/minTotal power rate: 9.9KWPower rate of electric spindle: 6kWMaximum spindle speed: 18000r/minX-axis line: 3500mmY-axis line: 380mmZ-axis line: 330mmX-axis speed: 60m/minY-axis speed: 45m/minZ-axis speed: 30m/minExternal size: 4830×2000×2200mmWeight: about 1500kgCompany profile:We are leading manufacturer in China which specialized in aluminum processing machine,cnc machine,aluminum window door machine,Upvc,pvc profile window door making machines such as mitre saw ,corner crimping machine,corner connecting cutting saw,

Contact Now

☆ The feed system adopts imported linear guide pair, high precision and good stability☆ Driven by servo motor, synchronous belt drive, magnetic grid ruler length, using numerical control system control; Blanking size, blanking size change fast, easy to achieve automatic production ☆Numerical control system, can complete the profile of different sizes of automatic blanking☆ Two saw heads can automatically convert the Angle to achieve the Angle cutting of 90° profile☆ Imported carbide saw blade, high precision, high durability☆ Imported linear bearing motion pair, so that the working accuracy is

Contact Now

Aluminum CNC Double Head Mitre Saw MachineModel: LJZ2-CNC-550*6000First, Mainly used for aluminum curtain wall material. The cutting of the window material can also be used for the cutting of plastic profiles, the use of diamond saw blade.the outer diameter can reach 500-600mm, and the speed is high.

Contact Now

Feature1.Used for mullion cutting when PVC window adopt the welding technology.2. 2 saw blades are settled as 90° so that can realize two V shape cutting by one time clamping. High precision and efficiency3. Patent technology to prevent collapse cutting precede.4. Easily adjustable depth, and adjustable stable feeding speed.5. Automatic crossing cutting two mullion end in one time. Save profile cost and improve efficiency. Support arm ensure cutting precision.6. Special clamping device ensure safety operation.

Contact Now

LJZ2Z-CNC-550*4300Using cemented carbide saw blade, the outer diameter can reach 550,the linear speed is high, and the machining precision is high.High transmission precision, accurate positioning and stable operation.High precision spindle motor makes the saw blade rotate stably.Gas-liquid damping cylinder realizes uniform feed speed regulation and stable movement.Adopt micro spray cooling device.When the machine works, the saw blades with two saw heads can cut at the same time or separately.The machine head is fixed at an angle of 45° to ensure stable precision in long-te

Contact Now

☆ Mainly used for cutting industrial aluminum profiles, aluminum doors and Windows, curtain wall materials, also can be used for PVC and woodCutting and blanking of profiles.☆ The machine adopts numerical control technology and can complete automatic positioning cutting of different sizes of profiles.☆ Selected high-quality aluminum carbide saw blade, outer diameter up to 500, high wire speed, high processing accuracy.☆ CNC transmission adopts high standard rack and pinion, high transmission accuracy, accurate positioning, stable work.☆ High precision spindle ensures stable rotation of saw bla

Contact Now

600mm saw blade Arbitrary angle CNC double mitre saw for aluminum profileModel: LJB2B-CNC-600*6000Feature:Mainly used for industrial aluminum profiles, aluminum doors and Windows, curtain wall material cutting, can also be used cutting of PVC and wood profiles. The imported high-speed spindle direct connected motor is mounted with diamond saw blade.

Contact Now

Wide range of processing width and processing height to meet the processing of variety of profiles.Adopt high speed and high precision motorized spindle.

Contact Now